Example industry

Solar

Since 2000, Rimas has supplied both standalone and turnkey line solutions for the production of solar panels. Whether you are an established manufacturer or just investigating if a production startup is interesting for you, we can support you with matchings solutions or advice.

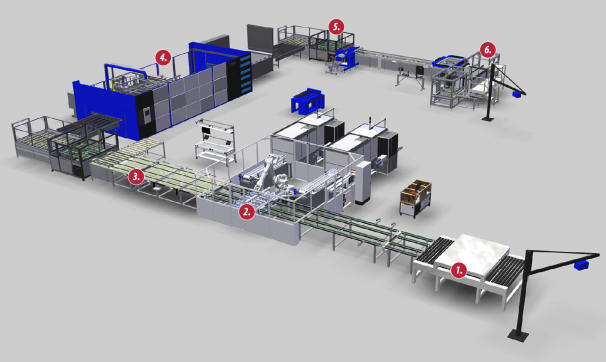

The Rimas standard flexible line

Rimas has developed a semi-automatic line as our standard solution. This line has a capacity of 65MW (30 panels per hour) and can be doubled in capacity to 130MW (60 panels per hour) with minimal investment.

The line is semi-automatic. Depending on your situation we can increase or decrease the level of automation. The automation scope includes steps such as: Interconnection, foil placement, load and unload functions etc. An example of the line is shown below, with links to short videos per production step.

1. Pre stringing

The first process step is the preparation and cleaning of the glass plate. This can be done either fully manually or automatically with pick and place systems, robots and glass washers. This step also includes the application of the first EVA foil sheet, again either manually or automatically.

Ook worden hier de benodigde folies gesneden en de eerste folie op de schone glasplaat gelegd.

2. Stringing

The so called “stringing”, connecting separate solar cells together into a large string, is one of the major processes. The quality of these strings are a key factor in the quality of the solar panel. We advise the use of a fully automated stringer. An operator fills cell trays with solar cells. The trays are fed into the machine automatically and the cells are soldered together with bus bar material. The stringer we preferably work with runs at 2100 cycles per hour. Next a robot picks up the strings and places them accurately on the prepared glass sheet. Advanced vision and sensor systems ensure proper placement of these strings next to each other.

Manual stringing is possible for small production volumes or research purposes. If this is of interest to you don’t hesitate to contact us.

3. Interconnection & repair

During this process step all strings are connected electrically to form a series. This is typically done manually with automated transport steps. Fully automated interconnection is becoming more and more financially interesting and we also have this solution as part of our portfolio.

We advise the carrying out of an electroluminescence test after the interconnection. This test generates an “X-ray” like image showing a clear picture showing if all areas of the cells generate electricity.

Repairs can be carried out in the next station if necessary.

4. Lamination

Lamination, merging together of the various foil layers in a vacuum oven, is the next crucial step for a good end result. Most important is an even heating of the laminate and a maximum removal of possible air between the various layers. We work together with European experts in this field. This allows us to build high speed lines that guarantee a perfect lamination quality. With these partners’ laminators we also have the possibility to laminate glass-glass panels at high speeds without special tools in the same line.

5. Back end

The back end adds the last elements to the panel, in the following steps:

- A visual inspection to verify lamination quality

- A trimming operation to remove excess foil

- Adding silicone or tape to fix the aluminium frame to the module

- Pressing the frame around the module

- Gluing and soldering the junction box that makes the electrical connection to the outside world.

All these steps can either be carried out manually, semi-automatic or fully automatic.

6. Sun simulation

At the end of the line tests are carried out to verify the quality of the end product. We advise the following tests at this position:

- Sun simulation/flashing: A light source simulates sun light, with which the power of the panel is measured

- PE/grounding test: this test verifies if the 4 frame parts are electrically connected to ensure proper grounding at installation.

- HV/High Voltage test: verifies that there is no electricity flowing from the network of cells to the frame of the panel, minimising the risk to the installer or user.

- Electroluminescence (EL) test: same as described before. This time not to allow for repairs but to allow for storage of quality data for future use (technical/commercial).